Discover the applications and benefits of micro stainless steel fiber in various industries. This article explores the versatility and advantages of using micro stainless steel fiber as a reinforcement material. From concrete reinforcement to electromagnetic shielding, understanding the capabilities of this innovative fiber is crucial for improving performance and durability in diverse applications.

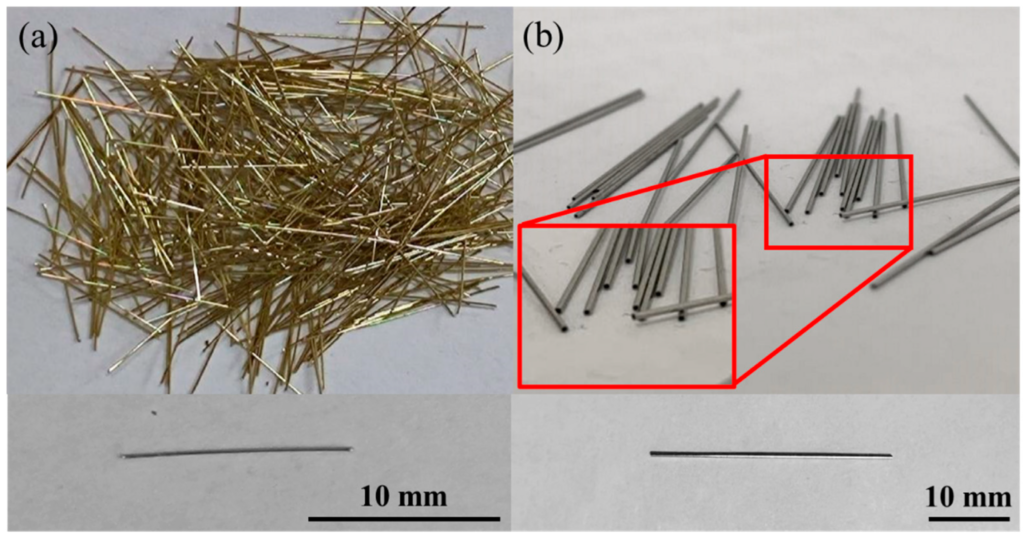

Micro stainless steel fiber is a revolutionary material that offers exceptional reinforcement properties in multiple industries. Its small size and high tensile strength make it a valuable addition to various applications, ranging from construction to electronics.

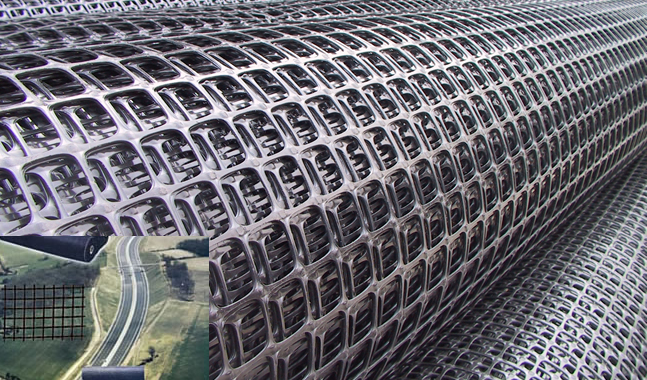

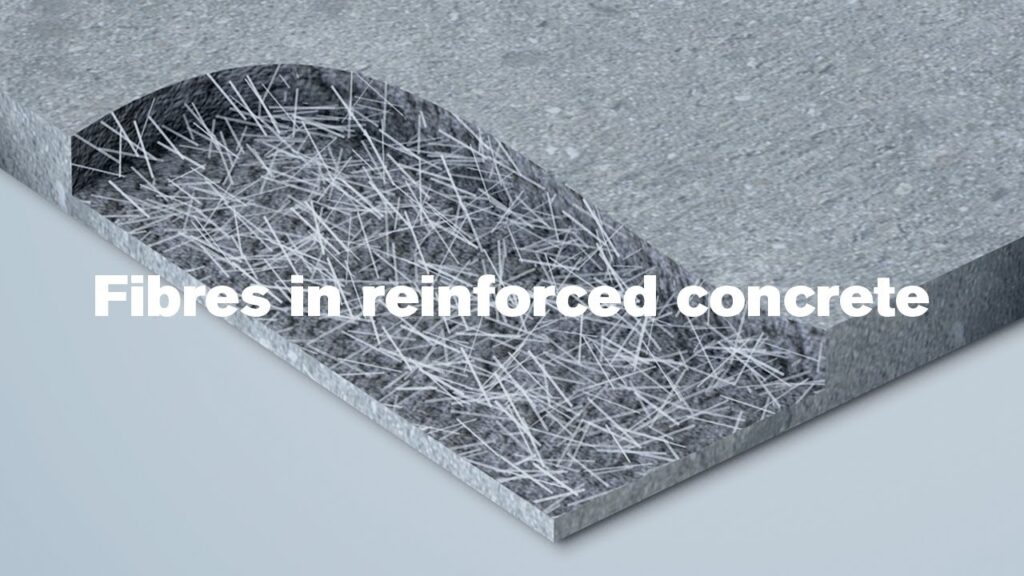

In the construction industry, steel fiber applicate as a reinforcement material in concrete. By adding this fiber to concrete mixtures, the resulting composite exhibits improved crack resistance, enhanced toughness, and increased durability. This reinforcement technique is particularly beneficial in applications such as industrial flooring, tunnel linings, and precast elements.

Another significant application of micro stainless steel fiber is in the field of electromagnetic shielding. The fiber’s conductive properties enable it to effectively block electromagnetic interference (EMI) and radio frequency interference (RFI).

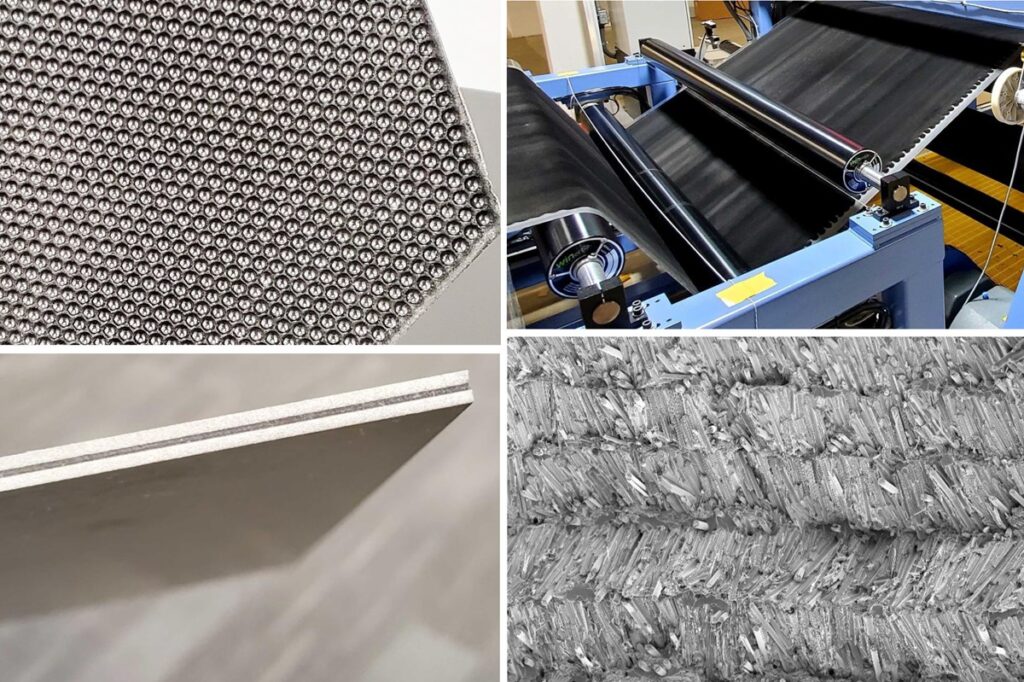

In the textile industry, steel fiber finds application in the manufacturing of high-performance fabrics. These fabrics offer superior heat resistance, electrical conductivity, and durability. They applicate in protective clothing for firefighters, military personnel, and workers in hazardous environments.

The benefits of incorporating steel fiber reinforcement are numerous. It enhances the strength and durability of materials, prolonging the lifespan of structures and reducing maintenance costs. The fiber’s high resistance to corrosion and extreme temperatures makes it suitable for challenging environments. Additionally, micro stainless steel fiber reinforcement provides improved impact resistance and crack control, ensuring structural integrity in demanding applications.

In summary, steel fiber offers a wide range of applications and benefits across industries. From concrete reinforcement to electromagnetic shielding and high-performance textiles, the versatility of this fiber contributes to enhanced performance, durability, and cost-effectiveness. By leveraging the potential of stainless steel fiber, businesses can achieve superior results in their respective fields.