Discover the benefits of using fiberglass mesh for concrete reinforcement. Learn how fiberglass mesh improves the tensile strength and crack resistance of concrete structures. Find out why fiberglass mesh is the ideal choice for enhancing the durability and longevity of your construction projects. Read now!

Introduction:

Fiberglass Mesh for Concrete1: Reinforcing the Foundation of Strength

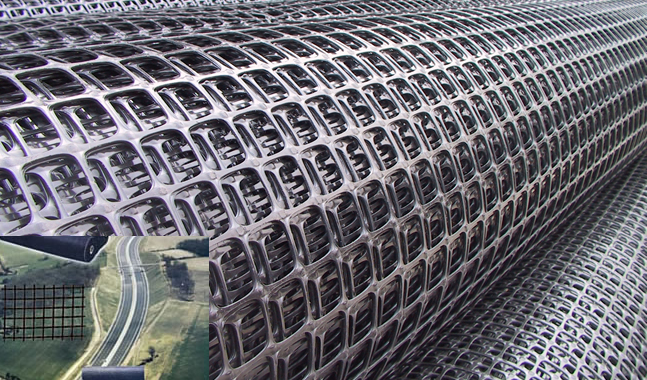

Fiberglass mesh is a vital component in concrete reinforcement, offering numerous advantages for construction projects. This versatile material enhances the strength, flexibility, and crack resistance of concrete structures. In this article, we will explore the benefits of using concrete reinforcement, its applications, and how it contributes to the durability and longevity of construction projects.

Benefits of Fiberglass Mesh for Concrete:

The Advantages of Reinforcing Concrete with Fiberglass Mesh

Fiberglass mesh provides several key benefits when used as reinforcement in concrete structures. Here are the advantages it offers:

- Enhanced Tensile Strength: This mesh improves the tensile strength of concrete, preventing cracks and enhancing structural integrity. It distributes stress more evenly, reducing the risk of concrete failure under load or during temperature fluctuations.

- Crack Resistance: By reinforcing concrete, this mesh helps minimize the formation and propagation of cracks. It acts as a barrier, limiting crack widths and preventing moisture penetration, which can lead to further deterioration.

- Flexibility and Versatility: Fiberglass mesh is highly flexible, allowing it to conform to various shapes and contours. It can be easily applied to curved or irregular surfaces, making it suitable for a wide range of construction projects.

Applications

Versatile Solutions for Construction Reinforcement

Fiberglass mesh finds extensive use in various applications where concrete reinforcement is required. Let’s explore some key areas:

- Residential Construction: This mesh is commonly used in residential construction for reinforcing concrete elements such as foundations, walls, and slabs. It helps prevent cracks and ensures the long-term stability of the structure.

- Infrastructure Projects: Fiberglass mesh plays a crucial role in infrastructure projects, including bridges, highways, and tunnels. It enhances the durability and load-bearing capacity of concrete structures, extending their lifespan and reducing maintenance needs.

- Commercial and Industrial Buildings: This mesh is utilized in commercial and industrial construction to reinforce concrete floors, columns, and beams. It improves the structural integrity and resistance to heavy loads, ensuring safe and long-lasting buildings.

Best Practices for Using Fiberglass Mesh in Concrete:

Key Considerations for Optimal Performance

To maximize the benefits of this type of concrete reinforcement, consider the following best practices:

- Proper Installation: Ensure the correct placement and embedding of the mesh within the concrete matrix. Follow the manufacturer’s guidelines for spacing, overlap, and anchoring to achieve optimal reinforcement.

- Compatibility: Select fiberglass mesh that is compatible with the specific concrete mix design and construction requirements. Consider factors such as alkali resistance, tensile strength, and dimensional stability.

- Quality Assurance: Regularly inspect the fiberglass mesh during installation and address any damage or defects promptly. Adhere to industry standards and quality control measures to ensure the effectiveness of the reinforcement.

Conclusion:

Durable Concrete Structures with this Mesh

Fiberglass mesh offers a reliable and effective solution for reinforcing concrete structures. Its ability to enhance tensile strength, crack resistance, and flexibility makes it indispensable in construction projects. Whether it’s residential buildings, infrastructure, or commercial structures, this mesh contributes to the longevity and durability of concrete elements.