In this comprehensive article, we will explore the remarkable properties of Galvanized Coated Steel Fiber for concrete reinforcement. This cutting-edge material is transforming the construction industry by significantly enhancing concrete strength and durability. From increasing structural integrity to improving crack resistance, galvanized coated steel fibers offer a cost-effective and efficient solution to reinforce concrete in various applications.

What is Galvanized Coated Steel Fiber for Concrete?

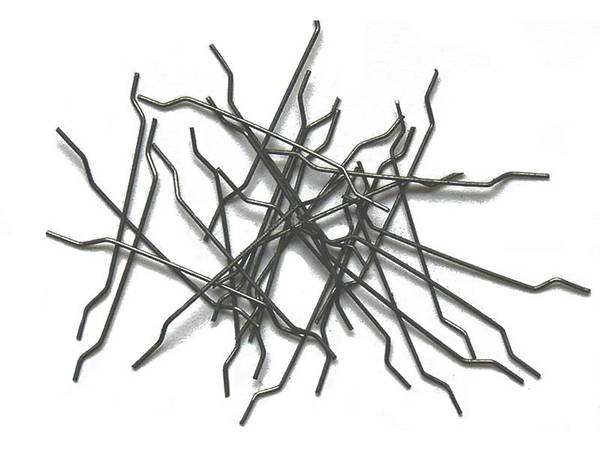

Galvanized Coated Steel Fiber is a specialized material designed to reinforce concrete. It consists of steel fibers coated with a layer of zinc to protect against corrosion, making it ideal for projects in harsh environments or those exposed to chemicals and moisture.

Advantages of Galvanized Coated Steel Fiber Reinforcement

The incorporation of Steel Fiber in concrete yields numerous benefits. Firstly, it enhances the concrete’s tensile strength, enabling it to withstand heavy loads and preventing cracks from propagating. Secondly, its excellent corrosion resistance extends the lifespan of the concrete structure, reducing maintenance costs significantly.

Applications in High-Performance

Concrete Galvanized Coated Steel Fiber finds extensive use in high-performance applications. For instance, it is popular in the construction of industrial floors, pavements, and precast elements, where durability and longevity are paramount.

Improved Crack Control and Durability

One of the key advantages of Steel Fiber reinforcement is its ability to control cracks in concrete. By inhibiting crack propagation and enhancing ductility, it ensures the overall integrity of the structure and reduces the risk of structural failure.

Real-Life Example: Galvanized Coated

Steel Fiber in Bridge Construction A notable example of this technology’s success is its application in bridge construction. Bridges are exposed to extreme environmental conditions, including heavy traffic and temperature fluctuations. By incorporating galvanized coated steel fibers in the concrete, bridges gain increased durability and resilience, prolonging their service life.

Best Practices for Using Galvanized Coated Steel Fiber

To maximize the benefits of Galvanized Coated Steel Fiber reinforcement, certain best practices should be followed. This includes proper dosage, mixing techniques, and curing procedures to ensure optimal performance and consistency.

Dosage and Mixing Techniques

The correct dosage of Galvanized Coated Steel Fiber is crucial for achieving the desired results. Engineers must carefully calculate the appropriate amount based on the project’s specifications. Additionally, using proper mixing techniques ensures the even distribution of fibers throughout the concrete matrix.

Curing Procedures for Optimal Performance

Proper curing is essential to allow the concrete to gain strength and durability over time. Adequate moisture and temperature control during the curing process is vital to ensure the galvanized coated steel fibers can contribute fully to the concrete’s performance.

Conclusion

Galvanized Coated Steel Fiber for concrete reinforcement offers a revolutionary solution for improving the strength and durability of concrete structures. Its remarkable properties, such as enhanced tensile strength and crack control, make it a sought-after material in the construction industry. By adhering to best practices in its application, engineers and contractors can unlock the full potential of this technology, ensuring the longevity and reliability of concrete structures in various projects.

Incorporating Galvanized Coated Steel Fiber in concrete not only reinforces infrastructure but also paves the way for sustainable and long-lasting construction, setting new standards for the future of the industry.