Discover the advantages of using steel fibers for concrete reinforcement. This comprehensive article explores the benefits, applications, and manufacturing process of steel fibers. Learn how steel fibers enhance the strength, durability, and crack resistance of concrete structures.

Introduction:

Steel fibers have revolutionized the field of concrete reinforcement, offering numerous benefits over traditional reinforcement methods. This article provides a comprehensive guide to steel fibers for concrete, highlighting their advantages, applications, and manufacturing processes. By understanding the role of fibers in enhancing concrete strength and durability, construction professionals can optimize their projects and deliver structurally resilient creations. Explore real-world examples and gain insights into the effective utilization of fibers to reinforce concrete and ensure long-lasting, high-performance structures.

What are Steel Fibers for Concrete?

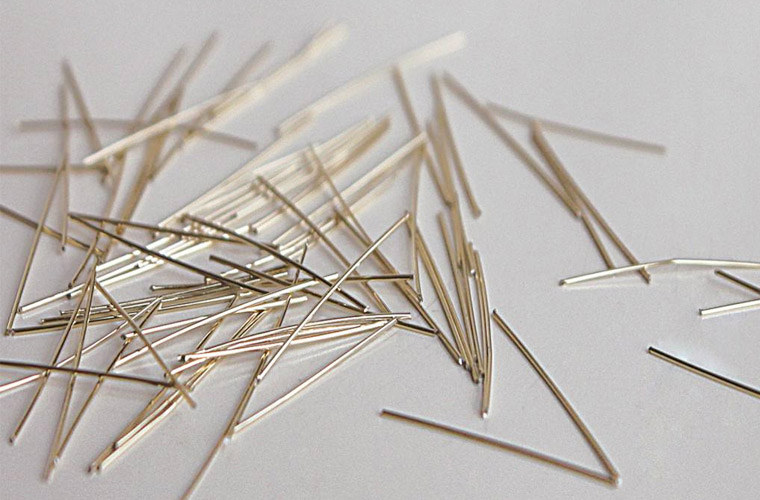

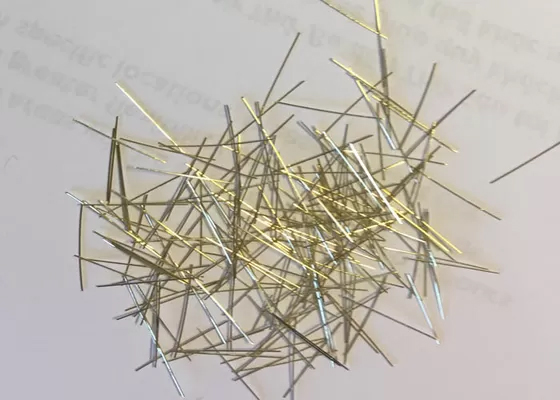

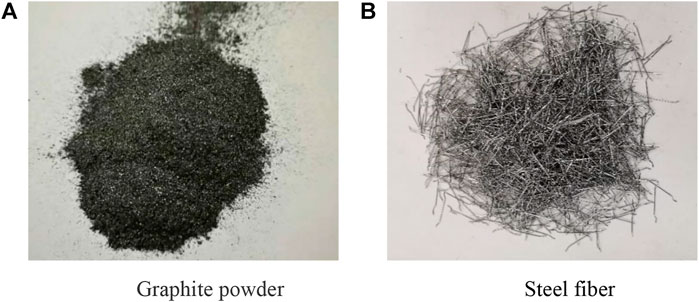

Steel fibers for concrete are small, discontinuous metallic fibers that can add to concrete mixtures to enhance their mechanical properties. When properly distributed, steel fibers improve the strength, ductility, and crack resistance of these structures.

Advantages of Steel Fibers for Concrete

Steel fibers offer several key advantages in concrete reinforcement. Firstly, they enhance the tensile and flexural strength of concrete, allowing for increased load-bearing capacity and resistance to cracking. Secondly, steel fibers improve impact resistance, reducing the risk of spalling and enhancing the durability of concrete structures. Additionally, these fibers provide excellent resistance to shrinkage and thermal cracking, improving the long-term performance of concrete.

Applications of Steel Fibers in Construction

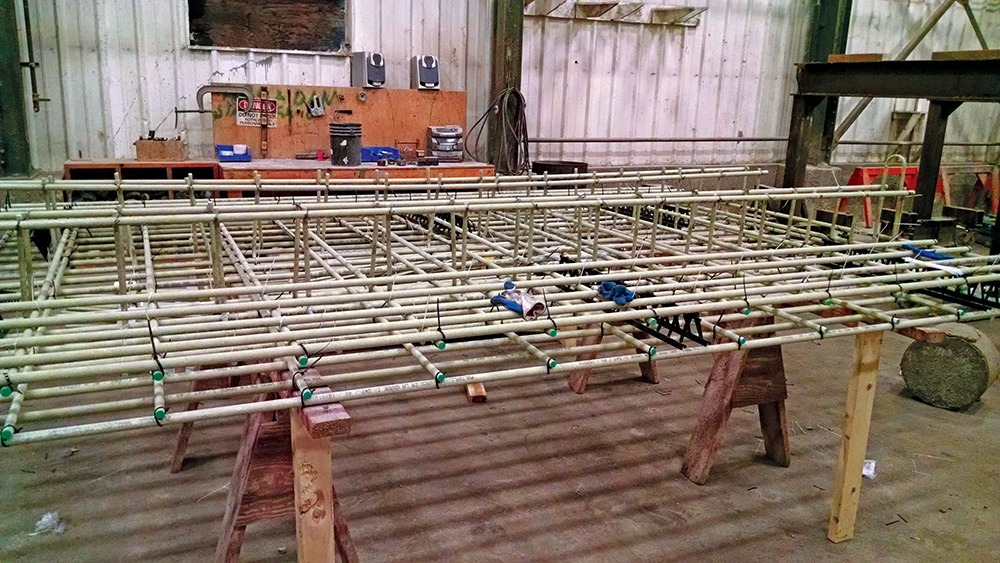

Steel fibers find applications in various construction projects where concrete reinforcement is required. They are commonly used in industrial flooring, precast elements, shotcrete applications, tunnel linings, and pavement construction. These fibers are particularly beneficial in high-stress areas, such as warehouses, bridges, and airports, where the demand for durable and crack-resistant concrete is critical.

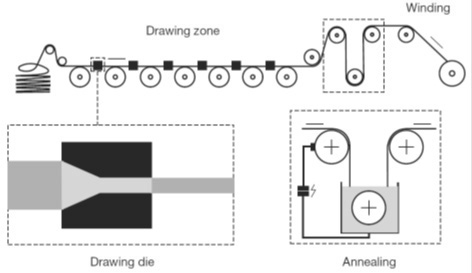

Manufacturing Process of Steel Fibers

The manufacturing process of steel fibers involves several stages. It begins with selecting high-quality steel wires with the desired tensile strength. The wires are then cut into predetermined lengths and undergo surface treatment to enhance bonding with the concrete matrix. Finally, the steel fibers are bundled or glued together in the desired volume or weight, resulting in a uniform and ready-to-use reinforcement material.

Real-World Examples

Numerous construction projects have witnessed the benefits of using these fibers for concrete reinforcement. For instance, in the construction of a high-rise building in City X, the addition of these fibers to the concrete mix improved the structural integrity and crack resistance of the floors, ensuring a safe and long-lasting structure. Similarly, in a highway construction project in City Y, the use of steel fibers in the pavement reduced the occurrence of cracks and increased the lifespan of the road, resulting in significant cost savings and improved road quality.

Conclusion:

These fibers have revolutionized concrete reinforcement by enhancing strength, durability, and crack resistance. Their numerous advantages, including increased load-bearing capacity, improved impact resistance, and resistance to shrinkage, make them a preferred choice in construction projects. By understanding the benefits and effective utilization of fibers for concrete reinforcement, construction professionals can optimize their projects and deliver robust and long-lasting structures. Embrace the strength and reliability of fibers and reinforce your concrete with confidence.