Steel fibers are an essential component in the production of high-strength, durable materials for various industrial applications. The manufacturing process of steel fibers involves several stages, including production, treatment, and finishing. In this article, we will provide a comprehensive guide to the steel fiber manufacturing process, highlighting the key stages and their importance.

Production of Steel Fibers

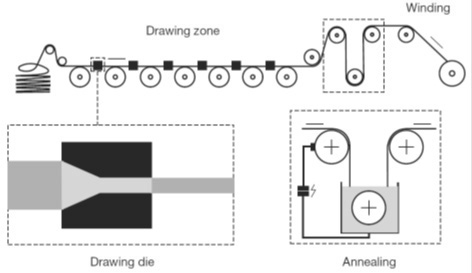

The production of steel fibers begins with the selection of high-quality steel wire. The wire is then drawn through a series of dies to reduce its diameter and increase its length. The drawing process involves several stages, each with a progressively smaller die, to achieve the desired diameter and length of the steel fiber.

Treatment of Steel Fibers

Once the steel fibers produce, they undergo various treatments to enhance their properties. These treatments include:

- Cleaning: The steel fibers cleaning to remove any impurities or contaminants that may affect their performance.

- Coating: A protective coating applies to the steel fibers to prevent corrosion and improve their durability.

- Heat Treatment: The steel fibers are subject to heat treatment to adjust their microstructure and improve their mechanical properties.

Finishing of Steel Fibers

The final stage of the steel fiber manufacturing process is finishing. This stage involves cutting the steel fibers to the required length and surface treatment to enhance their bonding properties. The finishing process includes:

- Cutting: The steel fibers cutting to the required length using advanced cutting equipment.

- Surface Treatment: The steel fibers treat with chemicals or coatings to improve their bonding properties with the matrix material.

Quality Control and Testing

Quality control and testing are crucial stages in the steel fiber manufacturing process. The quality of the steel fibers checks at every stage of the production process to ensure that they meet the required standards. The testing process includes:

- Chemical Analysis: The chemical composition of the steel fibers analyze to ensure that they meet the required specifications.

- Mechanical Testing: The mechanical properties of the steel fibers testing to ensure that they meet the required standards.

- Physical Testing: The physical properties of the steel fibers, such as their dimensions and surface roughness, are tested to ensure that they meet the required specifications.

Applications of Steel Fibers

Steel fibers have numerous applications in various industries, including:

- Construction: Steel fibers are used in the production of high-strength concrete, which is used in construction projects such as bridges, buildings, and roads.

- Automotive: Steel fibers are used in the production of automotive parts, such as brake pads and clutch disks.

- Aerospace: Steel fibers are used in the production of advanced materials for aerospace applications, such as aircraft structures and engine components.

Conclusion

In conclusion, the steel fiber manufacturing process is a complex and highly specialized process that involves several stages, including production, treatment, and finishing. The quality of the steel fibers is critical to their performance, and therefore, rigorous quality control and testing are essential. Steel fibers have numerous applications in various industries and play a crucial role in the production of high-strength, durable materials.

In summary, the steel fiber manufacturing process is a multi-stage process that involves production, treatment, and finishing. The process includes several quality control and testing stages to ensure that the steel fibers meet the required standards. Steel fibers have various applications in the construction, automotive, and aerospace industries.