Stainless steel fibers have gained popularity in recent years due to their unique properties and advantages. In this article, we will explore the stainless steel fiber advantages and why they are an excellent choice for different industries.

High Strength and Durability

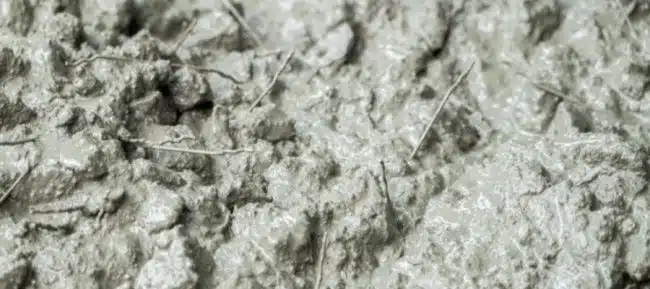

One of the stainless steel fibers advantages is their high strength and durability. These fibers are made from high-quality stainless steel, which is known for its resistance to corrosion and durability.

The fibers are designed to withstand harsh environments and can tolerate high temperatures. Making them ideal for applications that require longevity and strength.

Resistance to Corrosion

Stainless steel fibers are highly resistant to corrosion, which is a significant advantage in various industries. The fibers are made from stainless steel that is resistant to acidic and alkaline environments.

Making them suitable for use in chemical plants, marine environments, and other corrosive environments. This corrosion resistance ensures that the fibers can withstand harsh conditions and maintain their integrity, reducing the need for maintenance and replacement.

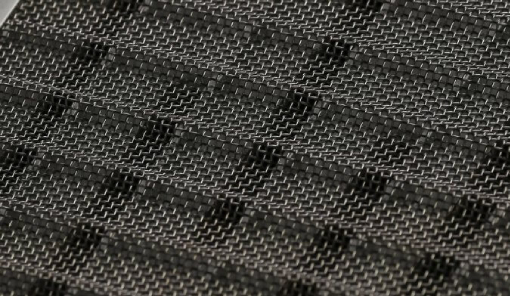

Flexibility and Versatility

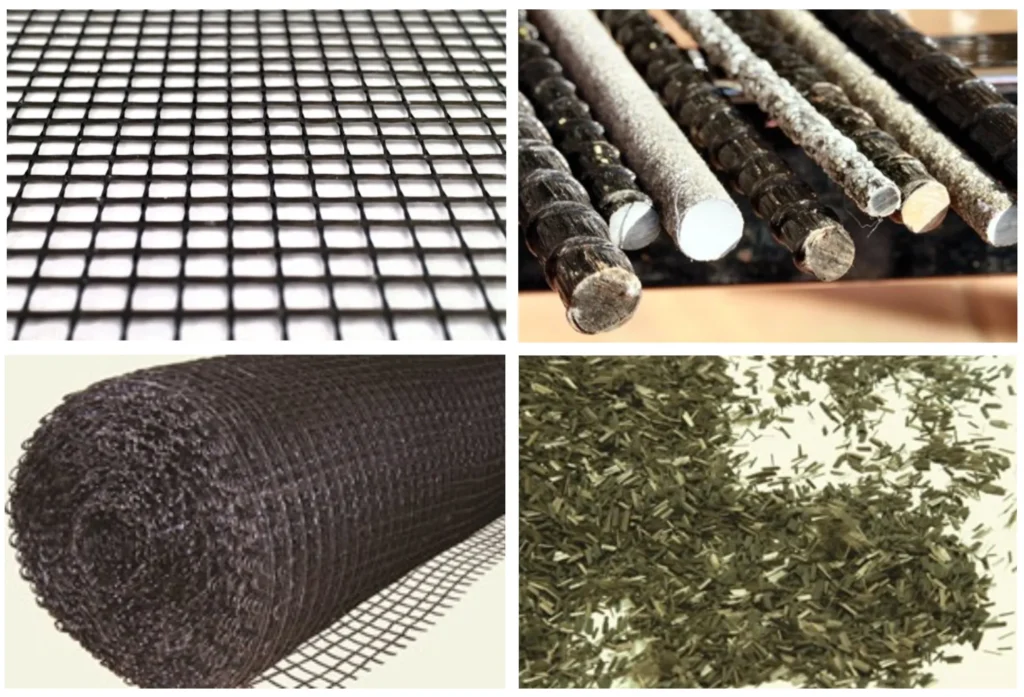

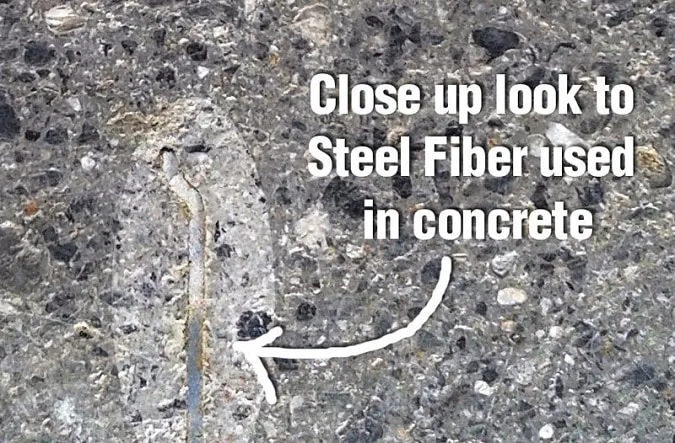

Stainless steel fibers are highly flexible and versatile, making them suitable for a range of applications. They can be woven into various shapes and forms, such as meshes, screens, and filters.

The fibers are popular in composite materials, such as fiberglass and carbon fiber, to enhance their strength and durability. This flexibility and versatility make stainless steel fibers an excellent choice for various industries, including aerospace, automotive, and medical.

Low Maintenance

Stainless steel fibers require minimal maintenance, which is a significant advantage for various industries. The fibers can be self-cleaning and do not require regular cleaning or maintenance. Additionally, this reduces downtime and increases productivity, making them an excellent choice for applications that require minimal maintenance.

Cost-Effective

Stainless steel fibers are cost-effective, making them an excellent choice for various industries. The fibers are made from high-quality stainless steel, which is durable and long-lasting.

This means that the fibers do not need to be replaced frequently, reducing costs associated with maintenance and replacement. Additionally, the fibers can be reused, further reducing costs.

Environmentally Friendly

Stainless steel fibers are environmentally friendly, making them a sustainable choice for various industries. This reduces waste and minimizes the impact on the environment, making them an excellent choice for industries that prioritize sustainability.

Examples of Applications

Stainless steel fibers have numerous applications across various industries. In the aerospace industry, they are popular in aircraft structures, engine components, and satellite parts.

In this industry, they are popular in brake pads, clutch plates, and engine components. Additionally, In the medical industry, they are popular in implants, sutures, and medical instruments.

Conclusion

Stainless steel fibers offer numerous advantages, including high strength and durability, resistance to corrosion, flexibility and versatility, low maintenance, cost-effectiveness, and environmental friendliness. Additionally, these advantages make them an excellent choice for various industries, including aerospace, automotive, medical, and more.

With their unique properties and benefits, stainless steel fibers are an essential component in modern manufacturing and will continue to play a significant role in shaping the future of various industries.

.jpg?x-oss-process=style/common)