This article explores the advantages of using steel fiber reinforced concrete (SFRC) and highlights the leading suppliers of steel fibers for concrete applications. Discover how steel fibers enhance the strength, durability, and performance of concrete structures in various industries.

Introduction:

Steel fiber reinforced concrete (SFRC) is revolutionizing the construction industry by enhancing the strength, durability, and performance of concrete structures.

This article highlights the benefits of SFRC and introduces the leading suppliers of steel fibers for concrete applications. By understanding the advantages and selecting the right steel fiber supplier, construction professionals can unlock the potential of SFRC and create robust and long-lasting structures.

Benefits of Steel Fiber Reinforced Concrete (SFRC):

The inclusion of steel fibers in concrete offers several advantages that significantly improve its performance. Here are some key benefits:

- Increased Crack Resistance: Steel fibers distribute stress more evenly. Reducing the formation and propagation of cracks in concrete, and enhancing its structural integrity.

- Improved Impact and Fatigue Resistance: SFRC exhibits enhanced resistance to impact loads and cyclic loading. Making it suitable for structures subjected to heavy traffic, dynamic loads, and seismic events.

- Enhanced Durability: Steel fibers provide increased resistance to harsh environments. Such as freeze-thaw cycles, chemical exposure, and abrasion, ensuring the longevity of concrete structures.

- Design Flexibility: SFRC allows for greater design freedom. Enabling the construction of thinner and lighter elements without compromising strength or durability.

Choosing the Right Steel Fiber for Your Concrete Projects:

Consider the following factors when selecting a steel fiber supplier for your concrete projects:

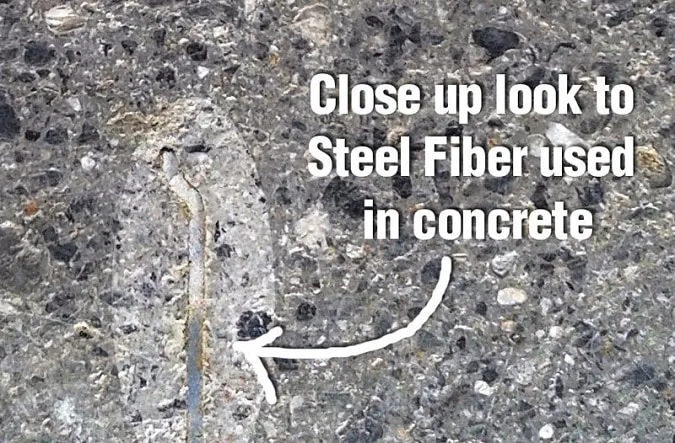

- Fiber Type and Geometry: Evaluate the different types of steel fibers available, such as hooked, crimped, or straight, and their specific geometries to ensure compatibility with your project requirements.

- Fiber Dosage: Determine the appropriate fiber dosage based on the desired concrete properties, structural requirements, and project specifications.

- Quality and Certification: Choose a supplier that provides high-quality steel fibers manufactured according to international standards and holds relevant certifications.

- Technical Support and Expertise: Look for suppliers who offer technical support, guidance, and expertise in steel fiber reinforced concrete applications, assisting you in optimizing your project’s performance.

Example:

For example, in the construction of industrial flooring, steel fiber suppliers play a vital role in ensuring the durability and performance of the concrete. Steel fibers effectively control cracking caused by shrinkage, temperature changes, and heavy loads, thereby minimizing maintenance and repair costs. By collaborating with reliable steel fiber suppliers, construction professionals can incorporate high-quality steel fibers into their concrete mix designs, resulting in superior industrial flooring that can withstand the demands of heavy machinery, foot traffic, and chemical exposure.

In conclusion, steel fiber reinforced concrete (SFRC) offers numerous benefits, including increased crack resistance, improved impact and fatigue resistance, and enhanced durability. By selecting the right steel fiber supplier and incorporating high-quality steel fibers into concrete projects, construction professionals can optimize the strength, durability, and longevity of their structures. Explore the possibilities of SFRC and unleash the potential for superior construction solutions.