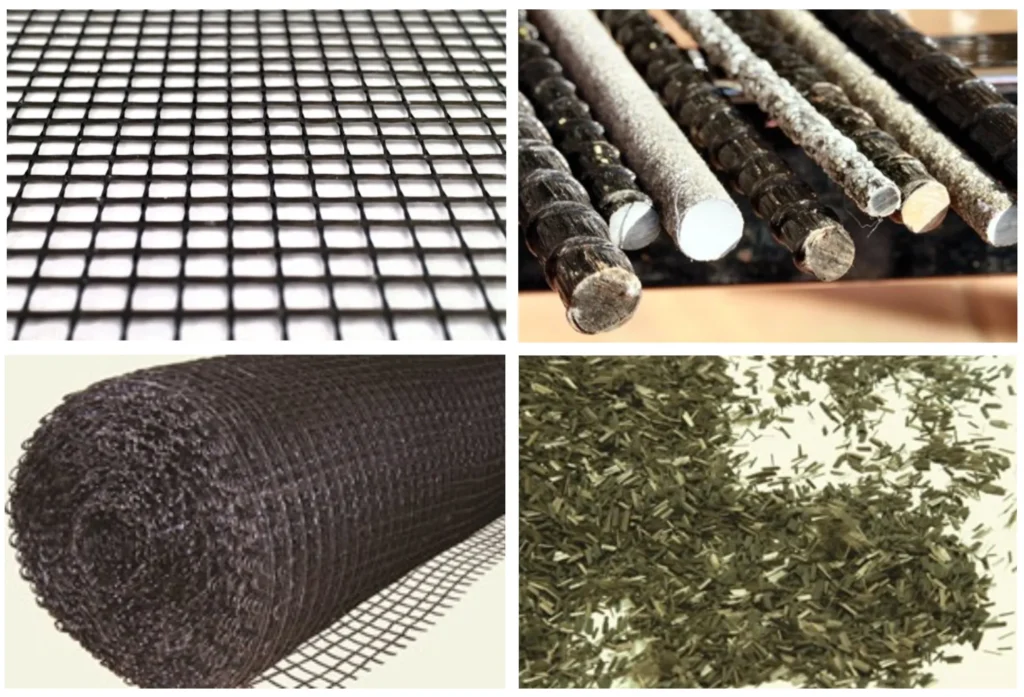

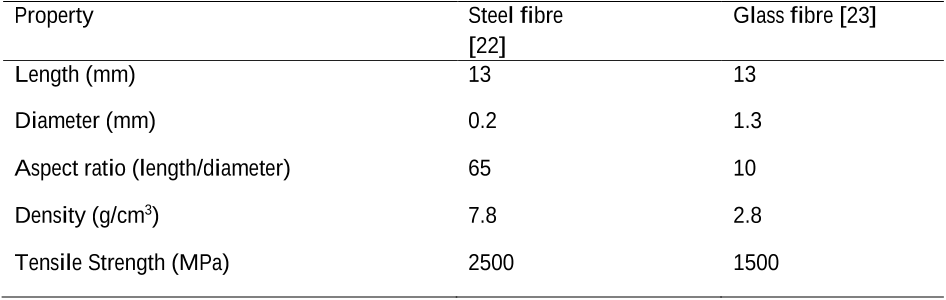

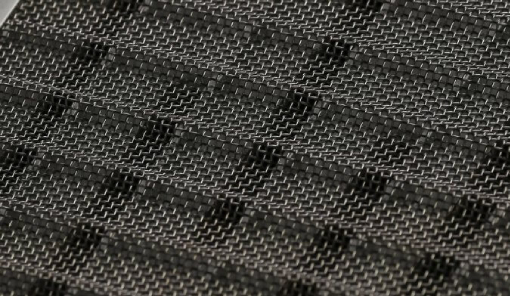

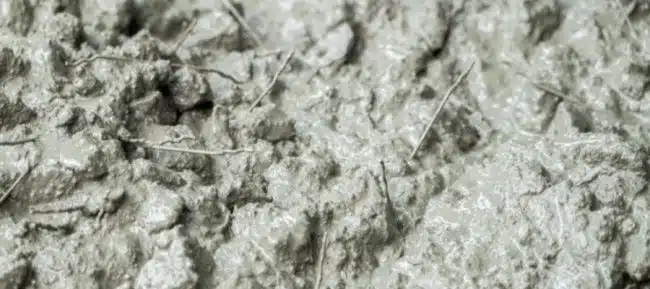

Steel fibers with hooked ends are a type of reinforcing material used in construction and engineering applications. The hooked end provides a secure connection between the fiber and the surrounding material, ensuring that the fiber remains in place and provides maximum reinforcement.

Hook End Steel Fiber Reinforcing Suppliers

There are several suppliers of hook end steel fibers, each offering its unique products and services. When selecting a supplier, it is important to consider factors such as the quality of the fibers, the size and shape of the hook, and the price. Some of the top suppliers of hook end steel fibers include:

- Fiber-Reinforced Polymer (FRP) Supply: FRP Supply offers a range of hook end steel fibers made from high-quality materials. They have a variety of sizes and shapes available, and their fibers are designed to provide maximum reinforcement in concrete and other materials.

- Composite Reinforcement Technologies (CRT): CRT is a leading supplier of composite reinforcement materials, including hook end steel fibers. They offer a range of products that are designed to meet the needs of various applications, from construction to aerospace.

- Glass Fiber Reinforced Concrete (GFRC) Supply: GFRC Supply offers a range of hook end steel fibers designed specifically for use in glass fiber reinforced concrete. Their fibers are made from high-quality materials and are available in a variety of sizes and shapes.

Benefits of Using Hook End Steel Fibers

There are several benefits to using hook end steel fibers in construction and engineering applications. Some of the most significant advantages include:

- Improved Durability: Hook end steel fibers provide maximum reinforcement in concrete and other materials, leading to improved durability and longevity.

- Reduced Maintenance: With their secure connection to the surrounding material, hook end steel fibers reduce the need for maintenance and repairs.

- Increased Strength: The use of hook end steel fibers can increase the strength of concrete and other materials, allowing for the creation of structures that can withstand heavy loads and harsh conditions.

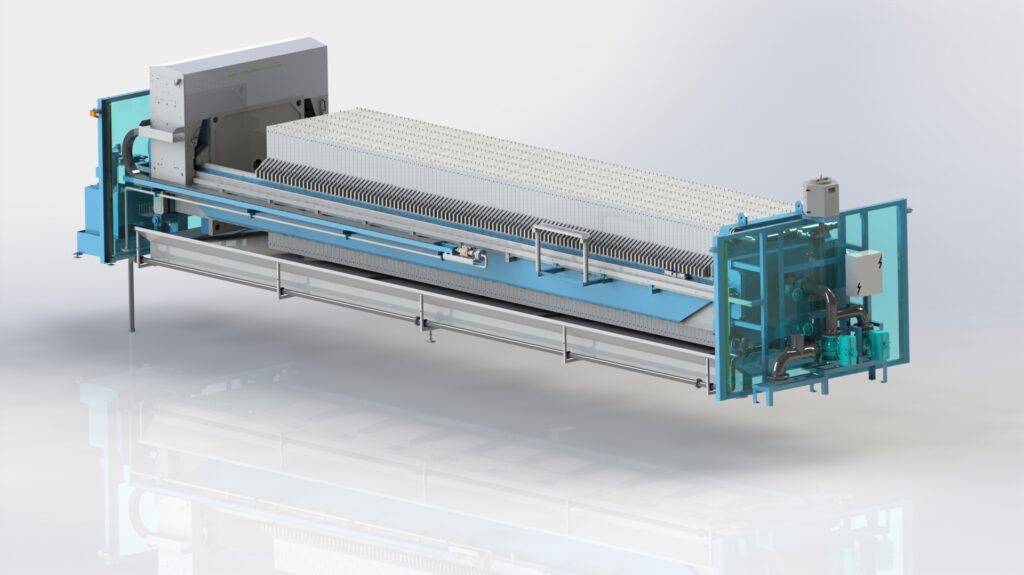

Examples of Applications

Hook end steel fibers can be used in a variety of applications, including:

- Concrete Pavements: Hook end steel fibers can be used to reinforce concrete pavements, improving their durability and reducing the need for maintenance.

- Building Structures: Hook end steel fibers can be used to reinforce building structures, such as beams and columns, improving their strength and durability.

- Bridge Decks: Hook end steel fibers can be used to reinforce bridge decks, reducing the risk of cracking and improving their overall durability.

Conclusion

Hook end steel fibers are a valuable reinforcing material used in construction and engineering applications. With their secure connection to the surrounding material and their ability to provide maximum reinforcement, hook end steel fibers are an excellent choice for a variety of projects.

When selecting a supplier, it is important to consider factors such as quality, size, shape, and price. By choosing the right supplier and using hook end steel fibers in their projects, engineers and contractors can ensure improved durability, reduced maintenance, and increased strength in their structures.

.jpg?x-oss-process=style/common)