Optimizing the performance of forward curved centrifugal fans can lead to significant energy savings in various applications.

Here are some energy-saving strategies to consider:

- Variable Speed Drives (VSDs): Install variable speed drives to control the speed of the fan motor based on actual airflow requirements. This allows the fan to operate at lower speeds during periods of lower demand, reducing energy consumption.

- Efficient Motor Selection: Choose high-efficiency motors, such as those meeting IE3 or IE4 efficiency standards, to power the forward curved centrifugal fan. Upgrading to more efficient motors can reduce energy losses and improve overall system efficiency.

- Regular Maintenance: Implement a proactive maintenance program to ensure the fan operates at peak efficiency. This includes regular cleaning of fan blades, inspection of belts and bearings, and lubrication of moving parts. Proper maintenance prevents unnecessary energy losses due to inefficiencies or mechanical problems.

- Optimized System Design: Design the ventilation or HVAC system to minimize resistance to airflow, such as reducing the number of bends and restrictions in the ductwork. Well-designed systems reduce the workload on the fan, leading to energy savings.

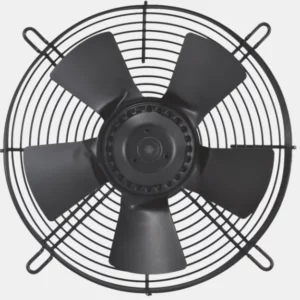

- Use of Efficient Components: Select energy-efficient components such as fan impellers, motors, and drives specifically designed for optimal performance in forward curved centrifugal fan applications. axial fan Upgrading to high-efficiency components can improve overall system efficiency and reduce energy consumption.

- Airflow Control Devices: Install dampers, inlet vanes, or other airflow control devices to modulate airflow based on demand. These devices help maintain optimal airflow rates while reducing energy consumption by avoiding overventilation.

- System Integration: Integrate the forward curved centrifugal fan with building automation or control systems to optimize fan operation based on occupancy schedules, temperature setpoints, or other parameters. Automated control ensures that the fan operates efficiently and only when necessary.

- Airflow Balancing: Regularly monitor and balance airflow within the ventilation system to ensure that air is distributed evenly to all areas. Proper airflow balancing prevents overventilation in some areas and underventilation in others, optimizing energy usage.

- Energy Recovery Systems: Consider integrating energy recovery systems, such as heat exchangers or enthalpy wheels, into the ventilation system to recover and reuse energy from exhaust air. Energy recovery reduces the load on the forward curved centrifugal fan and associated heating or cooling equipment, leading to energy savings.

- Occupancy Sensors: Install occupancy sensors in areas served by the ventilation system to automatically adjust fan operation based on occupancy levels. This prevents unnecessary fan operation in unoccupied spaces, reducing energy consumption.

By implementing these energy-saving strategies, you can optimize the performance of forward curved centrifugal fans and achieve significant energy savings in ventilation, air conditioning, and HVAC systems.