This comprehensive guide explores the features, advantages, and uses of SFRC. With its superior mechanical properties, SFRC enhances the strength, ductility, and durability of concrete structures. By understanding its composition, reinforcement mechanism, and implementation practices, you can achieve resilient and long-lasting constructions in areas such as industrial flooring, bridge decks, and seismic zones.

The Features and Advantages of Steel Fiber Reinforced Concrete

Steel fiber reinforced concrete offers the following features and advantages:

- Enhanced Strength: The inclusion of steel fibers significantly enhances the tensile and flexural strength of concrete. Reducing the risk of cracking and improving structural performance.

- Increased Durability: SFRC exhibits improved resistance to impact, abrasion, and fatigue. Making it suitable for high-traffic areas and structures subjected to harsh environmental conditions.

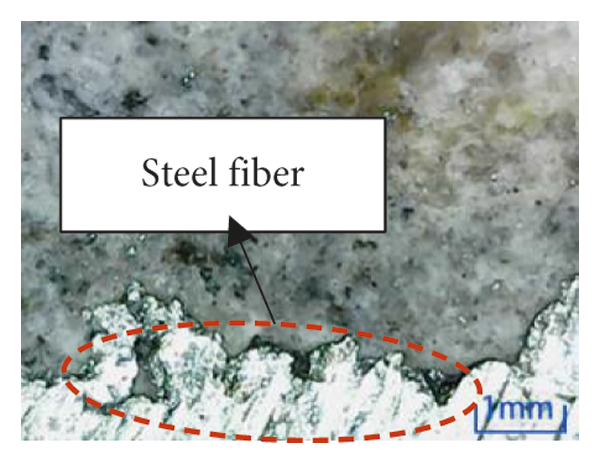

- Crack Control: Steel fibers act as crack arrestors, distributing stresses and preventing crack propagation. Thereby enhancing the overall durability and service life of the concrete.

Applications

Steel fiber reinforced concrete finds applications in various construction sectors, including:

- Industrial Flooring: SFRC is widely used in industrial settings, and warehouses. And parking lots to provide high-strength, abrasion-resistant, and crack-resistant flooring solutions.

- Bridge Decks: SFRC is employed in bridge construction to enhance durability. Resist cracking due to heavy loads and temperature variations, and improve the overall structural integrity of the bridge decks.

- Seismic Zones: In earthquake-prone regions, SFRC helps improve the performance of structures. By providing additional ductility and crack control, ensuring the safety of occupants.

Implementation and Best Practices for Steel Fiber Reinforced Concrete

The implementation and best practices for the reinforced concrete include:

- Mix Design: Proper mix design is crucial to achieving the desired performance of SFRC. Considering factors such as fiber type, dosage, aspect ratio, and compatibility with other concrete constituents.

- Fiber Dispersion: Adequate dispersion of steel fibers throughout the concrete mixture is essential to ensure uniform reinforcement and consistent mechanical properties.

- Placement and Compaction: Proper placement and compaction techniques are vital to achieve full encapsulation of steel fibers and avoid fiber clustering or balling.

- Quality Control: Regular quality control measures, including fiber content verification and testing of fresh and hardened concrete properties, help ensure the desired performance of SFRC.

Conclusion:

This type of reinforced concrete offers significant advantages in terms of strength, durability, and crack control, making it a valuable construction material for various applications. Whether in industrial flooring, bridge decks, or seismic zones, SFRC enhances the structural performance and extends the service life of concrete structures.

By implementing the features, advantages, and best practices highlighted in this guide, you can achieve resilient and long-lasting constructions. Steel fiber reinforced concrete provides a reliable solution to meet the demands of modern construction, delivering enhanced strength, durability, and crack resistance.