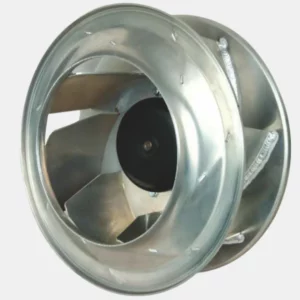

EC (Electronically Commutated) backward curved centrifugal fans play a crucial role in supporting material handling operations in industrial facilities by providing efficient and reliable airflow for various applications.

Here’s how EC backward curved centrifugal fans support material handling:

- Air Conveyance: EC backward curved centrifugal fans are used to convey air in material handling systems, such as pneumatic conveying systems or material transfer systems. They generate airflow that transports bulk materials, powders, granules, or other particulate matter through ducts, pipes, or chutes to different processing or storage locations within the facility.

- Dust Collection: In material handling operations where dust or airborne particles are generated, EC backward curved centrifugal fans are employed in dust collection systems to capture and remove particulate matter from the air. These fans create negative pressure within dust collection units, drawing contaminated air through filtration media or cyclone separators to trap dust particles before releasing clean air back into the environment.

- Material Drying and Cooling: EC backward curved centrifugal fans are used in industrial drying and cooling processes to circulate air and remove moisture or heat from bulk materials. They facilitate evaporation and cooling by directing airflow over the surface of wet or hot materials, accelerating the drying or cooling process and enhancing productivity.

- Material Separation: EC backward curved centrifugal fans are utilized in material separation systems, such as air classifiers or cyclones, to separate different components or sizes of bulk materials based on their aerodynamic properties. ec backward curved centrifugal fan These fans create airflow patterns that carry lighter particles upward for collection, while heavier particles settle downward for further processing or disposal.

- Agitation and Mixing: In material handling applications where blending, agitation, or mixing of bulk materials is required, EC backward curved centrifugal fans can be used to create turbulent airflow patterns within mixing vessels or silos. This promotes homogeneity and uniformity in material composition, ensuring consistent product quality and performance.

- Pressure Conveyance: EC backward curved centrifugal fans are capable of generating high-pressure airflow, making them suitable for pressure conveying systems used in material handling operations. They provide the necessary force to transport materials against resistance, such as uphill conveyance or through long-distance pipelines, ensuring efficient material transfer and distribution.

- Controlled Airflow: With their variable speed control capability, EC backward curved centrifugal fans offer precise control over airflow rates and pressures in material handling systems. This allows operators to adjust airflow parameters based on changing production requirements, material characteristics, or process conditions, optimizing system performance and energy efficiency.

Overall, EC backward curved centrifugal fans play a vital role in supporting material handling operations in industrial facilities by providing efficient and controlled airflow for conveying, dust collection, drying, cooling, separation, agitation, mixing, and pressure conveying of bulk materials. Their advanced design, energy efficiency, and variable speed control capabilities make them versatile and effective solutions for a wide range of material handling applications.