Brass coated steel fiber, a composite material made from a combination of steel and brass, has been gaining popularity in various industries due to its unique properties and advantages. We will explore the definition, benefits, and applications of brass coated steel fiber, and why it is becoming a go-to material for many manufacturers and engineers.

Definition and Properties

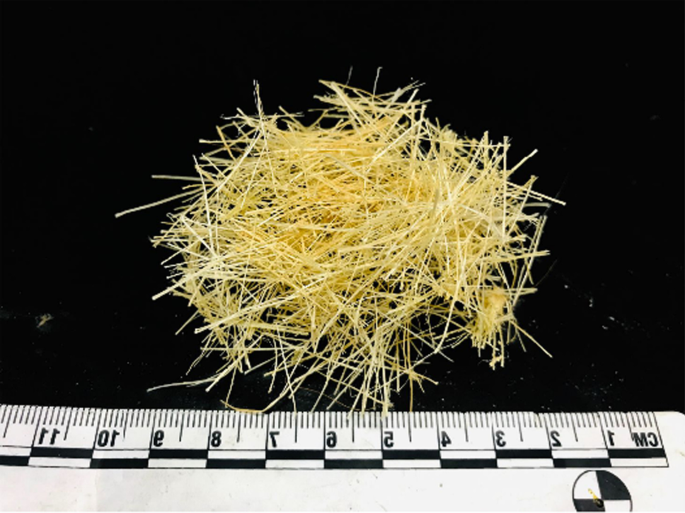

Brass coated steel fiber is a type of composite material that consists of a steel core coated with a thin layer of brass. The steel core provides strength and durability, while the brass coating offers excellent corrosion resistance and a decorative appearance. The brass layer can be applied in various thicknesses, depending on the intended application and desired level of corrosion resistance.

The combination of steel and brass creates a material with unique properties that are not found in either steel or brass alone. Our steel fiber has a higher strength-to-weight ratio than steel, making it an ideal choice for applications where weight is a concern. It also has better corrosion resistance than steel, making it suitable for use in harsh environments.

Applications

Brass coated steel fiber has a wide range of applications across various industries, including:

- Aerospace: Due to its high strength-to-weight ratio and corrosion resistance, our steel fiber is used in aircraft and spacecraft components, such as fuel lines, hydraulic tubing, and structural components.

- Automotive: Brass coated steel fiber is used in automotive parts, such as brake lines, fuel lines, and other fluid carrying components, due to its resistance to corrosion and high temperatures.

- Construction: Our steel fiber is used in building structures, such as handrails, balustrades, and other decorative fixtures, due to its durability and aesthetic appeal.

- Marine: Our steel fiber is used in marine applications, such as boat hardware, fittings, and other components, due to its resistance to corrosion and ability to withstand exposure to seawater.

- Electrical: Our steel fiber is used in electrical applications, such as wiring and connectors, due to its conductivity and resistance to corrosion.

Benefits

The benefits of using brass coated steel fiber include:

- Corrosion resistance: Our steel fiber offers excellent corrosion resistance, making it suitable for use in harsh environments.

- High strength-to-weight ratio:Our steel fiber has a higher strength-to-weight ratio than steel, making it an ideal choice for applications where weight is a concern.

- Aesthetic appeal: Brass coated steel fiber has a decorative appearance, making it suitable for use in applications where aesthetics are important.

- Cost-effectiveness: Our steel fiber is often less expensive than pure brass, making it a cost-effective alternative for many applications.

Conclusion

Brass coated steel fiber is a versatile composite material that offers a range of benefits and applications. Its unique combination of steel and brass creates a material with high strength, low weight, and excellent corrosion resistance. With its decorative appearance and cost-effectiveness, brass coated steel fiber is becoming a go-to material for many manufacturers and engineers. Whether you’re in the aerospace, automotive, construction, marine, or electrical industry, brass coated steel fiber is worth considering for your next project.